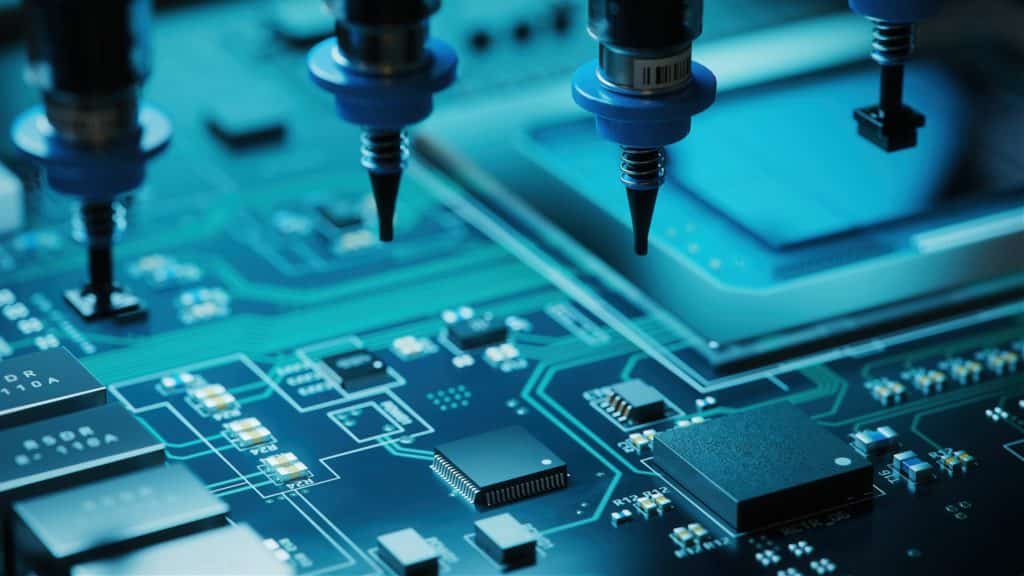

PCB (printed circuit board) assembly is a critical process in modern electronics manufacturing. It combines precision, expertise, and advanced technology to create reliable circuit boards used across various industries. Understanding the key aspects of this process can help businesses make informed decisions when seeking quality solutions from a PCB assembly manufacturer.

PCB Assembly: Explained

PCB assembly involves mounting electronic components onto a printed circuit board (PCB) to create a functional electronic device. This process typically includes component placement, soldering, and quality testing to ensure proper operation. Look for manufacturers that adhere to industry certifications such as ISO and IPC standards. The assembly process requires specialized equipment and skilled technicians to manage tasks such as surface mount technology (SMT) and through-hole soldering. SMT involves placing components directly onto the surface of the PCB, while through-hole technology involves inserting component leads into pre-drilled holes on the board.

The Role of a PCB Assembly Manufacturer

A professional PCB assembly manufacturer provides end-to-end services, from component sourcing to final product testing. These manufacturers have the expertise to handle various project complexities, ensuring quality and consistency in every batch produced. PCB assembly is vital to modern electronics manufacturing, requiring precision and expertise at every stage. Partnering with a trusted assembly manufacturer or contract manufacturer ensures high-quality, reliable products that meet specifications. They also play a crucial role in design support, offering insights on component selection, board layout optimization, and manufacturability. The assembly process requires specialized equipment and skilled technicians to manage tasks such as surface mount technology (SMT) and through-hole soldering. SMT involves placing components directly onto the surface of the PCB, while through-hole technology involves inserting component leads into pre-drilled holes on the board. This collaboration helps minimize design errors and improves the final product’s overall performance. This collaboration helps minimize design errors and improves the final product’s overall performance. In addition to assembly, they often offer prototyping services, allowing businesses to test and refine their designs before committing to full production runs.

Steps in the PCB Assembly Process

The assembly of a printed circuit board follows a series of precise steps:

The assembly of a printed circuit board follows a series of meticulous steps:

- Design Review: Before production begins, a thorough review of the PCB design ensures compatibility with manufacturing processes and component availability.

- Component Procurement: The manufacturer sources high-quality components based on the design specifications.

- Stencil Preparation: A stencil is created for applying solder paste precisely to areas where components will be mounted.

- Solder Paste Application: Solder paste is applied to the board using the stencil, preparing it for component placement.

- Component Placement: Automated pick-and-place machines position components accurately on the board.

- Soldering: The board undergoes reflow soldering, where the solder paste melts and solidifies, creating secure connections.

- Inspection and Testing: Quality control processes, including optical inspection and functional testing, ensure the assembly meets all specifications.

Why Use a PCB Contract Manufacturer?

Partnering with a PCB contract manufacturer offers several advantages, including:

- Expertise: Contract manufacturers have extensive experience handling complex PCB assemblies.

- Efficiency: Streamlined processes lead to faster production and shorter lead times.

- Cost-Effectiveness: Leveraging established supplier relationships often results in lower component costs.

- Quality Assurance: Rigorous testing protocols ensure every unit meets industry standards.

Factors to Consider When Selecting a PCB Contract Manufacturer

Choosing the proper contract manufacturer is crucial for ensuring product reliability and performance. Key factors include:

- Certifications and Standards Compliance: Look for manufacturers that adhere to industry certifications such as ISO and IPC standards.

- Manufacturing Capacity: Ensure the manufacturer can handle the volume and complexity of your project.

- Prototyping Capabilities: The ability to produce prototypes can accelerate product development.

- Supply Chain Management: A reliable manufacturer will have strong relationships with component suppliers to avoid delays.

Industry Applications of PCB Assembly

PCB assemblies are used in a variety of industries, including:

- Medical Devices: Ensuring high-precision electronics for critical medical equipment.

- Aerospace and Defense: Providing reliable circuit boards for mission-critical applications.

- Consumer Electronics: Supporting the development of smart devices and home appliances.

- Industrial Automation: Enhancing control systems and monitoring equipment.

Conclusion

PCB assembly is vital to modern electronics manufacturing, requiring precision and expertise at every stage. Partnering with a trusted assembly manufacturer or contract manufacturer ensures high-quality, reliable products that meet specifications. Look for manufacturers that adhere to industry certifications such as ISO and IPC standards. By understanding the key steps and considerations, businesses can make informed decisions that lead to successful product outcomes. This collaboration helps minimize design errors and improves the final product’s overall performance. Furthermore, a reliable partner offers peace of mind through consistent quality assurance, efficient production timelines, and robust testing protocols. As technology advances, working with a skilled manufacturer will be crucial in keeping up with industry innovations and market demands. If you produce prototypes or large-scale orders, the right manufacturing partner is key to long-term success and operational efficiency.