Introduction

Centerless grinding is a precision machining process that ensures the accurate shaping and finishing of cylindrical components without the need for centering or mounting. In Arlington Heights, this specialized service has become a cornerstone for industries demanding high-quality, precise, and efficient manufacturing solutions. This article delves into the benefits, applications, and key considerations for choosing centerless grinding services in Arlington Heights.

What is Centerless Grinding?

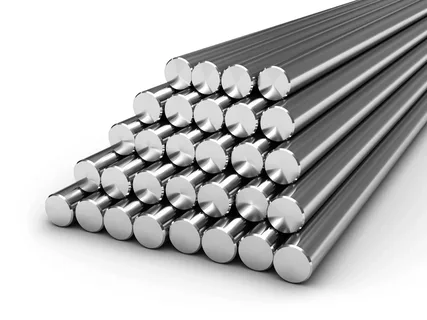

Centerless grinding is a method used to grind cylindrical objects without the need for center mounting. This process involves a workpiece placed between two wheels: the grinding wheel and the regulating wheel. The grinding wheel removes material from the workpiece, while the regulating wheel controls its rotation and feeds it through the machine. The absence of center mounting allows for continuous and efficient production, especially for long or thin parts.

Benefits of Centerless Grinding

- Precision and Accuracy: Centerless grinding delivers tight tolerances and high precision, which is crucial for applications requiring exact measurements and finishes.

- Efficiency: The process allows for high-speed production, making it ideal for large batches of parts. It reduces handling and setup time, resulting in cost savings for manufacturers.

- Versatility: This grinding method can handle a wide range of materials, including metals and plastics, and is suitable for various component sizes and shapes.

- Improved Surface Finish: Centerless grinding provides a smooth and consistent surface finish, which enhances the overall quality and functionality of the parts.

Applications of Centerless Grinding

- Automotive Industry: Used for grinding components such as shafts, rods, and pistons, centerless grinding ensures the precise dimensions required for optimal engine performance.

- Aerospace Industry: High precision is critical in aerospace components. Centerless grinding is employed to produce parts like landing gear components and hydraulic cylinders with strict tolerances.

- Medical Industry: Medical devices and implants benefit from the precision of centerless grinding, ensuring both functionality and safety.

- Industrial Machinery: Components such as bearings, gears, and spindles are manufactured with the necessary accuracy for reliable machinery operation.

Choosing the Right Centerless Grinding Service in Arlington Heights

- Expertise and Experience: Look for service providers with a proven track record in centerless grinding. Experienced professionals will have the skills and knowledge to handle complex requirements and deliver high-quality results.

- Quality Assurance: Ensure the service provider adheres to strict quality control measures. Certifications and industry standards are indicators of their commitment to excellence.

- Equipment and Technology: Modern, well-maintained equipment is essential for achieving precision in centerless grinding. Verify that the facility uses up-to-date machinery and technology.

- Customer Service: Good communication and customer support are crucial for addressing any concerns or requirements. A reliable service provider should offer clear consultations and responsive service.

Top Centerless Grinding Providers in Arlington Heights

- Company A: Known for its advanced technology and extensive experience in various industries, Company A offers high-precision centerless grinding services tailored to specific needs.

- Company B: With a focus on quality and efficiency, Company B provides comprehensive centerless grinding solutions, supported by state-of-the-art equipment and a dedicated team.

- Company C: Specializing in custom centerless grinding, Company C is recognized for its expertise in handling complex projects and delivering exceptional results.

Conclusion

Centerless grinding is an indispensable process for achieving high-precision and efficient manufacturing of cylindrical components. In Arlington Heights, businesses benefit from a range of top-tier service providers offering expertise, advanced technology, and superior quality. By choosing the right centerless grinding service, you can ensure that your components meet exacting standards and contribute to the success of your operations.

FAQs

1. What is the main advantage of centerless grinding over other grinding methods?

Centerless grinding provides higher efficiency and precision without the need for center mounting, making it ideal for high-volume production and tight tolerance applications.

2. Can centerless grinding be used for all materials?

Yes, centerless grinding is versatile and can handle various materials, including metals and plastics, depending on the specific requirements of the job.

3. How do I choose the best centerless grinding service provider?

Look for providers with a strong track record, modern equipment, strict quality control, and excellent customer service to ensure you receive high-quality results.

4. What types of components are commonly processed using centerless grinding?

Common components include automotive parts, aerospace components, medical devices, and industrial machinery parts.

5. How does centerless grinding affect the surface finish of components?

Centerless grinding provides a smooth and consistent surface finish, enhancing the overall quality and functionality of the components.

By considering these aspects, you can make an informed decision and select a centerless grinding service that meets your specific needs and expectations.

What is the main advantage of centerless grinding over other grinding methods?

Centerless grinding provides higher efficiency and precision without the need for center mounting, making it ideal for high-volume production and tight tolerance applications.

What is the main advantage of centerless grinding over other grinding methods?

Centerless grinding provides higher efficiency and precision without the need for center mounting, making it ideal for high-volume production and tight tolerance applications.