In the industrial world, hydraulic systems are vital to the smooth functioning of heavy machinery and equipment. These systems rely on hydraulic hoses and other components to operate efficiently and effectively. However, like all mechanical systems, they are prone to wear and tear over time, leading to potential breakdowns and costly downtime. For businesses in Arkansas that rely on hydraulic-powered equipment, having access to reliable hydraulic hose repair and hydraulic repair services is essential to maintaining productivity and minimizing operational interruptions. This guide explores the importance of hydraulic hose repair, industrial hose services, and the overall significance of hydraulic repair services in Arkansas.

The Importance of Hydraulic Systems in Industrial Operations

Hydraulic systems are used across a wide range of industries in Arkansas, including agriculture, construction, manufacturing, mining, and transportation. These systems work by using fluid to generate, control, and transmit power, enabling machinery to perform heavy-duty tasks. The key components of a hydraulic system include pumps, valves, cylinders, and, of course, hoses that transport hydraulic fluid.

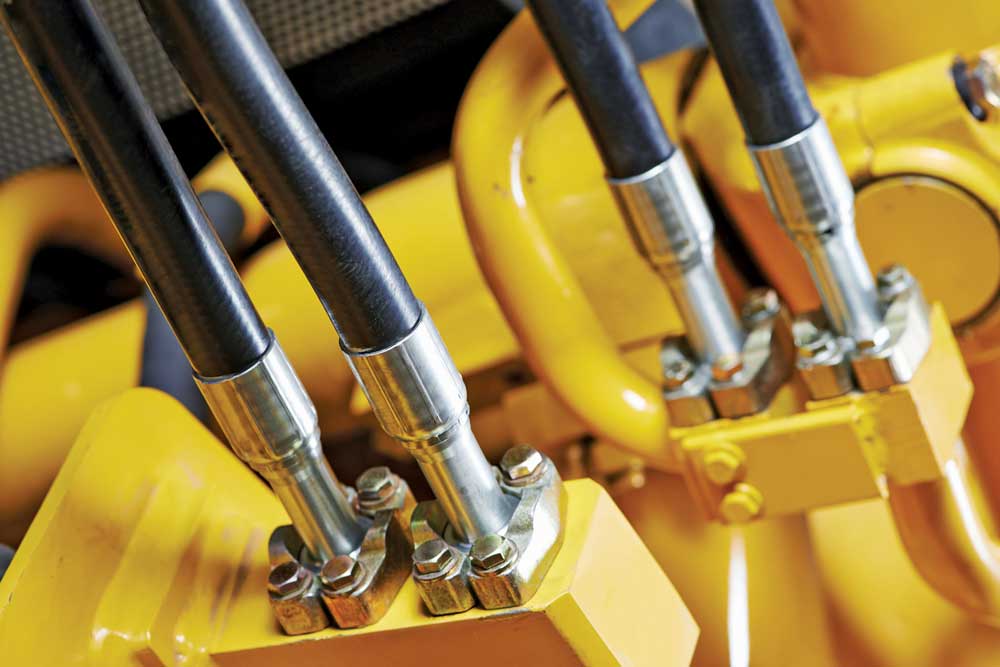

Hydraulic hoses are flexible tubes made of rubber, thermoplastic, or other synthetic materials designed to convey fluid between different components of the system. These hoses are subjected to extreme pressures, temperatures, and mechanical stress, making them one of the most vulnerable parts of any hydraulic system. A failure in a hydraulic hose can lead to fluid leaks, system inefficiencies, and, in some cases, complete system breakdowns.Hydraulic Repair Services Arkansas

Signs That You Need Hydraulic Hose Repair

Hydraulic hose issues can arise due to various factors, such as wear and tear, improper installation, exposure to harsh environmental conditions, or simply the natural aging of materials. Knowing the warning signs of hydraulic hose failure can help prevent larger, more expensive problems down the line. Some common indicators that your hydraulic hose may need repair or replacement include:

Visible Cracks and Leaks: One of the most obvious signs of a damaged hydraulic hose is fluid leaking from the hose itself or its fittings. Cracks or abrasions on the outer surface of the hose often indicate that the hose material has degraded.

Reduced System Performance: If your hydraulic system is not operating at full capacity, it could be due to a restriction in the hose caused by internal damage or a partial blockage.

Bulges or Blisters on the Hose: Bulges or blisters are signs of weakened sections in the hose, which are at risk of rupturing under pressure.

Unusual Noises: Whistling or hissing sounds may indicate a leak in the hydraulic hose or a problem with the fluid flow.

Loose Fittings: Over time, hose fittings can loosen, leading to fluid leaks and poor system performance. Inspecting fittings regularly and tightening or replacing them as needed is crucial to maintaining system integrity.

Hydraulic Hose Repair Services in Arkansas

When a hydraulic hose fails, the key to minimizing downtime is fast and reliable repair services. In Arkansas, numerous hydraulic repair specialists offer services to quickly address issues and get your equipment back up and running. Here are some of the most common services provided by hydraulic hose repair professionals:

On-Site Hydraulic Hose Repair: Many repair companies in Arkansas offer mobile services that come directly to your worksite. This is particularly valuable in industries like construction, agriculture, or mining, where bringing heavy machinery to a repair shop may not be feasible. On-site repairs help reduce downtime by providing immediate solutions to hose failures and other hydraulic system issues.

Custom Hose Fabrication: If a replacement hose is needed, many hydraulic service providers can fabricate custom hydraulic hoses to meet specific requirements. This ensures that the new hose is compatible with your machinery and meets the exact specifications needed for optimal performance.

Hose Testing and Diagnostics: Before performing a repair, many hydraulic service technicians will conduct pressure tests and other diagnostics to assess the condition of the hose and identify any underlying issues. This step helps prevent future breakdowns and ensures the system is operating safely and efficiently.

Fittings and Coupling Services: In many cases, hydraulic hose failure is caused by worn or damaged fittings. Hydraulic repair companies offer a wide range of fittings, couplings, and adapters, allowing them to repair or replace faulty connections as needed.

Preventive Maintenance: Regular maintenance of hydraulic systems and hoses is crucial to avoiding unexpected failures. Many hydraulic repair companies in Arkansas offer preventive maintenance programs that include inspections, hose replacement schedules, and fluid checks to ensure that your system remains in optimal condition.

The Importance of Industrial Hose Services in Arkansas

In addition to hydraulic hoses, industrial hoses are also widely used in various sectors for the transfer of liquids, gases, and other materials. These hoses play a vital role in industries such as oil and gas, chemical processing, food and beverage production, and more. Just like hydraulic hoses, industrial hoses are subject to wear and tear and require regular inspection and maintenance to ensure their longevity and effectiveness.

Industrial hose services in Arkansas include repair, replacement, and maintenance of hoses used in different applications, such as chemical transfer, fuel handling, water discharge, and air supply. Reliable industrial hose services are critical for maintaining smooth operations in industries where precision and safety are paramount.

Hydraulic Repair Services in Arkansas: Comprehensive Solutions

While hydraulic hose repair is a significant part of hydraulic maintenance, it is only one aspect of the broader hydraulic repair services offered in Arkansas. Hydraulic systems are complex and consist of numerous interconnected components that require attention. Hydraulic repair companies provide a wide range of services, including:

Pump and Motor Repair: Hydraulic pumps and motors are essential for the movement of fluid through the system. Over time, these components can wear out or fail, leading to reduced system performance. Repair or replacement of pumps and motors ensures that the hydraulic system can operate at full capacity.

Cylinder Repair and Rebuilding: Hydraulic cylinders are responsible for converting fluid pressure into mechanical force. If a cylinder is leaking or malfunctioning, it can compromise the entire system. Cylinder repair services include seal replacement, honing, and, if necessary, complete cylinder rebuilding.

Valve Repair and Replacement: Valves regulate fluid flow within a hydraulic system. Damaged or malfunctioning valves can lead to pressure imbalances and poor system performance. Hydraulic repair services often include valve repair, reseating, and replacement to maintain system efficiency.

System Diagnostics and Troubleshooting: When a hydraulic system is not performing as expected, diagnostic services can help identify the root cause of the issue. Technicians use advanced tools and techniques to pinpoint problems within the system, allowing for targeted repairs that minimize downtime. Hydraulic Hose Maintenance

Preventive Maintenance Programs: Just as with hydraulic hoses, preventive maintenance programs for the entire hydraulic system are essential to avoiding costly breakdowns. These programs include regular inspections, fluid analysis, and scheduled part replacements to ensure that the system remains in peak condition.

Conclusion: The Value of Professional Hydraulic and Industrial Hose Services

For businesses in Arkansas that rely on hydraulic and industrial systems, maintaining these systems is critical to ensuring operational efficiency and avoiding costly downtime. Hydraulic hose repair, industrial hose services, and comprehensive hydraulic repair services are all essential to keeping your equipment running smoothly.

By working with experienced professionals who offer fast, reliable repairs, preventive maintenance, and custom solutions, businesses can avoid prolonged equipment downtime and extend the life of their hydraulic systems. Whether you are in construction, agriculture, manufacturing, or another industry, having access to quality hydraulic repair services in Arkansas can significantly enhance the productivity and profitability of your operations.