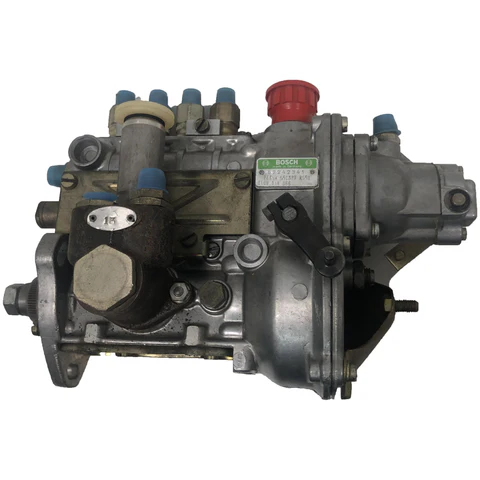

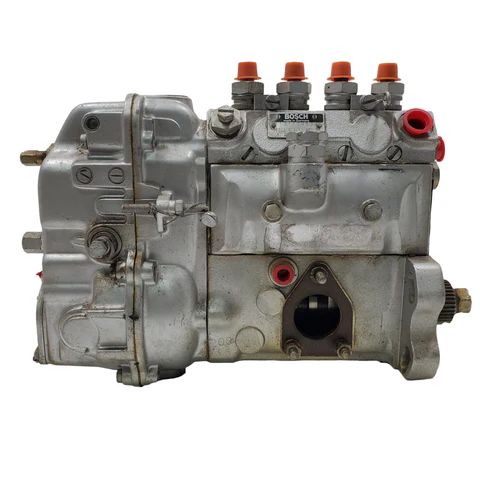

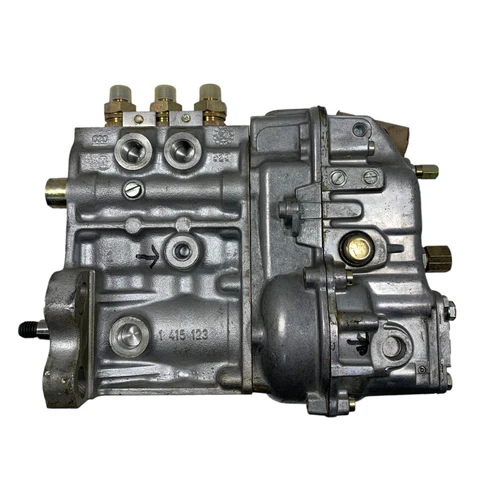

A high-pressure fuel injection pump is an essential component in modern internal combustion engines, designed to deliver fuel efficiently at high pressure for optimal combustion. Unlike traditional low-pressure fuel systems, high-pressure fuel injection pumps enhance performance, fuel economy, and emissions control. At Goldfarb Associates, we understand the importance of advanced fuel injection technology in improving engine efficiency.

How a High-Pressure Fuel Injection Pump Works

Role in the Fuel Delivery System

A high-pressure fuel injection pump pressurizes fuel before delivering it to the injectors, ensuring precise atomization for better combustion. The improved fuel spray pattern leads to more efficient burning of fuel, enhancing both power and fuel economy.

Difference Between Low-Pressure and High-Pressure Systems

- Low-Pressure Fuel Injection: Uses fuel injectors that operate at 30-60 PSI (pounds per square inch), leading to incomplete combustion.

- High-Pressure Fuel Injection: Delivers fuel at up to 30,000 PSI, ensuring finer atomization and better mixing with air.

Types of High-Pressure Fuel Injection Systems

- Common Rail Fuel Injection (CRDI) – Uses a rail to supply fuel to injectors at high pressure, improving efficiency.

- Direct Injection (DI) – Injects fuel directly into the combustion chamber, increasing power and reducing emissions.

- Gasoline Direct Injection (GDI) – Found in modern gasoline engines for improved performance and mileage.

At Goldfarb Associates, we specialize in high-performance fuel injection systems that maximize efficiency and longevity.

Key Advantages of a High-Pressure Fuel Injection Pump

Improved Fuel Atomization

High-pressure pumps break fuel into tiny droplets, ensuring better mixing with air. This results in more complete combustion, reducing fuel wastage and increasing engine output.

Enhanced Engine Performance and Power

Engines equipped with high-pressure fuel injection pumps experience faster throttle response, better acceleration, and increased horsepower. Vehicles benefit from smoother and more efficient operation.

Increased Fuel Efficiency

By ensuring complete combustion, high-pressure fuel injection systems reduce fuel wastage, leading to better mileage and lower fuel costs. This makes it ideal for both personal and commercial vehicles.

Reduced Emissions

Efficient combustion leads to fewer unburned hydrocarbons and lower NOx emissions, helping vehicles meet strict environmental regulations.

Optimized Air-Fuel Ratio

With precise fuel injection timing, a high-pressure pump ensures the engine runs with the ideal air-fuel mixture, reducing engine knocking and improving efficiency.

Better Cold Start Performance

Cold weather often causes starting issues in engines. A high-pressure fuel injection pump helps ignite fuel faster, reducing crank time and improving reliability.

Greater Durability and Longevity

Designed to withstand extreme pressures, high-pressure fuel injection pumps last longer than conventional pumps. However, regular maintenance is crucial, and Goldfarb Associates recommends periodic inspections to maintain peak performance.

Applications of High-Pressure Fuel Injection Pumps

High-pressure fuel injection pumps are widely used in various industries:

- Passenger Vehicles: Improves performance in both gasoline and diesel cars.

- Performance and Racing Cars: Enhances throttle response and speed.

- Heavy-Duty Trucks and Industrial Machinery: Maximizes fuel efficiency in commercial fleets.

- Marine and Aviation Engines: Essential for fuel-efficient operation in aircraft and boats.

Goldfarb Associates provides high-quality fuel injection solutions tailored for different applications, ensuring reliable performance.

Maintenance and Care for High-Pressure Fuel Injection Pumps

Use Clean, High-Quality Fuel

Contaminated fuel can damage injectors. Always use top-tier fuel and additives to prevent deposits.

Regularly Replace Fuel Filters

Fuel filters prevent debris from entering the injection system. Goldfarb Associates recommends replacing them every 10,000-15,000 miles.

Avoid Contaminated or Low-Quality Fuel

Low-quality fuel may contain excessive ethanol, which damages fuel pumps and injectors over time.

Perform Routine Inspections and Servicing

Professional diagnostics can detect early signs of wear or clogging, ensuring smooth operation. Goldfarb Associates offers expert maintenance services to extend your pump’s lifespan.

Challenges and Potential Downsides

Despite their benefits, high-pressure fuel injection pumps come with some challenges:

- Higher Initial Cost – More expensive than low-pressure alternatives.

- More Complex Maintenance – Requires skilled technicians for repairs.

- Sensitivity to Fuel Contamination – Dirty fuel can clog injectors and affect performance.

- Potential for High-Pressure System Leaks – High-pressure systems require leak-free connections to function properly.

By following Goldfarb Associates maintenance guidelines, you can mitigate these challenges and ensure a long-lasting, high-performance fuel system.

Conclusion

A high-pressure fuel injection pump offers numerous benefits, including improved fuel atomization, better fuel efficiency, enhanced power, and reduced emissions. It plays a crucial role in modern vehicles and industrial engines, making it a vital upgrade for anyone looking to enhance engine performance.

At Goldfarb Associates, we provide top-tier fuel injection solutions designed for efficiency and durability. Whether you’re looking for high-performance parts or expert maintenance tips, trust Goldfarb Associates to keep your engine running at peak performance.

FAQs

What is the difference between a high-pressure and low-pressure fuel injection pump?

A high-pressure fuel injection pump delivers fuel at significantly higher pressures (up to 30,000 PSI) for better combustion, while a low-pressure pump operates at much lower levels (30-60 PSI), leading to incomplete fuel atomization.

How does a high-pressure fuel injection pump improve fuel efficiency?

By ensuring finer fuel atomization and complete combustion, high-pressure pumps reduce fuel wastage and increase mileage.

Are high-pressure fuel injection pumps suitable for all vehicles?

Yes, they are commonly used in modern gasoline and diesel engines, especially in direct injection systems. Many performance and commercial vehicles also benefit from them.

What are the common signs of a failing high-pressure fuel injection pump?

Symptoms include poor acceleration, misfires, rough idling, excessive smoke emissions, and reduced fuel efficiency. If you notice any of these, visit Goldfarb Associates for diagnostics and repairs.

How can I maintain my high-pressure fuel injection pump for long-term reliability?

- Use clean, high-quality fuel

- Replace fuel filters regularly

- Avoid fuel contamination

- Perform routine inspections with a professional like Goldfarb Associates